TRANSCAL heat exchangers are installed and used all over the world. Our facilities are located in, among others, Canada, Germany, Switzerland, Spain, France, Saudi Arabia and Panama. They perfectly meet the needs and requirements of many types of industries. Their facilities are today the best ambassadors of the Transcal exchanger.

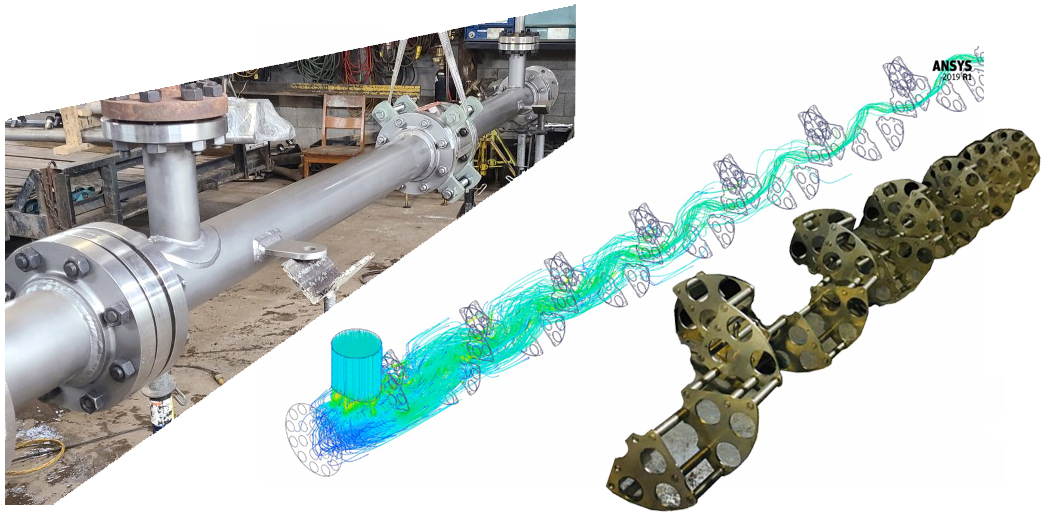

CanmetEnergy Laboratories - Ottawa, Canada

We delivered a TRANSCAL heat exchanger for CanmetEnergy Laboratories - Ottawa to test energy processes. A Stainless Steel Heat Exchanger with a duty power of 152,530 Btu / h, length 3.56 m and diam. 14 cm, very compact compared to conventional tubular heat exchangers for the same duty. This Air - Nitrogen Heat Exchanger was designed and manufactured according to the ASME VIII div I standard, with an expansion joint and a gaskets supporting the conditions of use and ensuring optimal safety.

Sainte-Hyacinthe Research and Development Center for food industry - Canada

For the Research and Development Center for Food Industry in Sainte-Hyacinte, we delivered two modular TRANSCAL heat exchangers, in polished Stainless Steel, intended for the food industry. A double safety head, made up of a set of flanges and sealing gaskets, replaces welding, which ensures long lifecycle of the Heat Exchanger and prevents any risk of infiltration which could contaminate food fluids; in addition to ensuring very easy cleaning. Click here for more details on these equipments.

Car manufacturer Renault, Valladolid - Spain

After many attempts with conventional tubular exchangers and plate heat exchangers, quickly fouled, the Transcal heat exchanger was selected by an engineering firm. For more than five years, Transcal Heat Exchanger works without fouling problems and requires less chutdown for maintenance.

This German company is a manufacturer of steam generators. We have created for this factory a series of heat exchangers adapted to their specific needs.More than 600 heat exchangers have been installed in many industries using steam: heat recovery in laundries, recovery of steam before returning to the feed tank, etc.

Swiss Center for Electronics and Microtechnology (CSEM)

For this high-tech company, we studied and solved a very complicated problem; The electron guns must be cooled, but under an absolute condition that the cooling system does not subject them to any vibration, otherwise the precision necessary for the engraving of chips would be disturbed. In addition, the temperature should be set to an accuracy of ± 0.5 ° C and the total noise of the device should not exceed 42 decibels. After testing the prototype, 15 devices were ordered.

This company manufactures car wash stations under the name Hypromat. In order to wash cars with hot water (chassis and engines) and to protect high pressure pumps that do not support hot water, we have designed and manufactured small heat exchangers that provide service at a pressure of 100 bar.

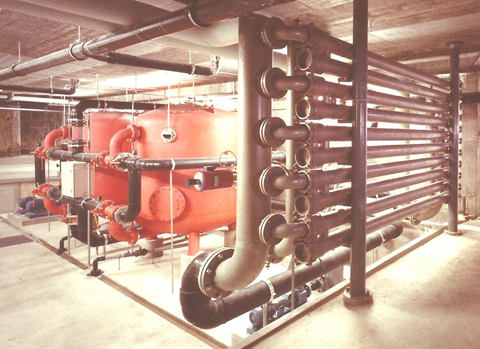

Thermal Station of Yverdon-les-Bains

The Thermal Station of Yverdon-les-Bains is known for the quality of its thermal water, sulfur springs arise from the ground at 29 ° C. To exploit this potential energy, a Transcal heat exchanger was coupled with a heat pump.

Swiss chocolate factory, Suchard has a factory that produces white chocolate in Spain. The cocoa butter had an unpleasant taste. After study and tests in our laboratory, we proposed a Transcal exchanger, calculated to eliminate this odor. The result was entirely conclusive.

During pasteurization, in most heat exchangers, milk deposits crusts that harden in the exchange tubes. These deposits give a taste of caramel, poorly come for a yogurt manufacture. In order to solve this problem, we have created a system of heat exchange stages and have been able to eliminate this defect.

Refrigerated boats

The banned Freon, due to ozone destruction, has been replaced by various other products. We have supplied ammonia/seawater heat exchangers on request. Transcal heat exchangers' flexibility has allowed them to be installed in tight spaces where conventional heat exchangers could not be installed. The materials have been chosen accordingly, special stainless steel or titanium, has given complete satisfaction.

During the construction of this college, we were asked to recover the maximum energy at the exit of the boilers. Knowing that in general, the fumes at the outlet of boilers have a temperature of about 150 ° C, we have provided exchangers lowering these temperatures to 50 ° C through the recovery of the latent heat of the steam. The acid condensates were brought into a neutralization box. This installation has recovered 40,000 kcal/h or 46.5 kW.

KREBS in Zurich has ordered a heat exchanger to cool chlorine, a product with a very high aggressivity. We have chosen a heat exchanger with a bundle of titanium tubes and distribution columns coated with natural rubber.

Wet paint stripping facility using N-methylpyrrolidone. Several types of exchangers have been manufactured and installed in this factory: a double-coat rotary column, a thin-film heat exchanger for "bottom-of-column reboiling" and a conventional Transcal heat exchanger for heating the product.