Thermal

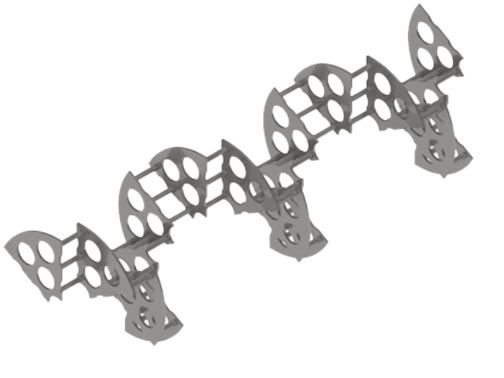

With the Transcal heat exchanger, the fluid moving in shell side is forced, by a system of spiral baffles, to take a helical flow. This form of flow makes it possible to increase the fluid velocity, therefore the exchange coefficient, without increasing the pressure drop. Or, by a spacing of these baffles, lower the pressure drops to save pumping energy.

This transverse and spiral flow system makes it possible, compared with conventional tube heat exchangers, to increase the heat exchange coefficients of several products having a higher viscosity than water.

The ability to maintain constant flow velocities by reducing the spaces between the baffles during steam condensation, allows the Transcal heat exchanger to have a very small exchange area compared to conventional heat exchangers, allowing to lower the price and reduce the size of the heat exchanger considerably.

Click on the opposite images to see how it works.

Security

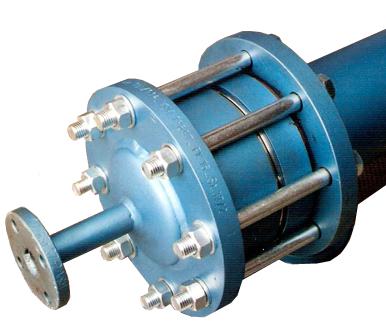

A special design of the Transcal exchanger's head makes it impossible to mix the primary and secondary fluids, even in the case of a gasket failure. This is very important to the food industry, chemical industry, etc. This absolute guarantee of the liquids purity is impossible to have with conventional heat exchangers, wich the break of a welding leads to the mixing of primary and secondary fluids.

Modular geometry

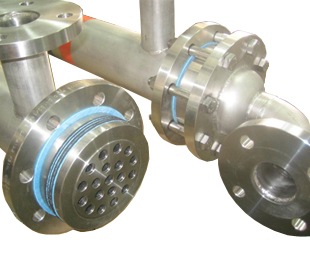

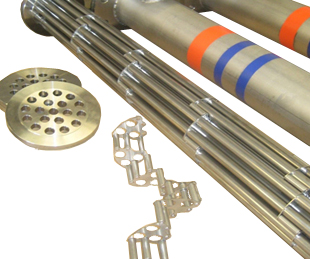

The compactness of the Transcal heat exchanger and its modular construction make it ideal for limited spaces. The device can be installed horizontally or vertically in short and numerous modules, or in long and smaller numbers, depending on the available space and the required capacity.

Design flexibility

With the modularity of the Transcal heat exchanger, it is possible to adjust the internal structure of the exchanger or add other exchanger units, to meet a new change in flow rates, temperatures, pressure drop, or other characteristics of the fluids.

Design and manufacturing

The cut-to-length tubes are assembled without welding in prefabricated heads and maintained by a unique system of flexible seals, which ensure a guaranteed sealing up to 100 bar. All parts being prefabricated, the manufacturing time of a Transcal heat exchanger is very short.

Cost

The only custom built heat exchanger at serial price. Manufacturing the parts in series significantly lowers manufacturing costs. As soon as there is steam or a liquid other than pure water, the size of the Transcal heat exchanger is up to 8 times smaller, and no technology can match its competitive price.

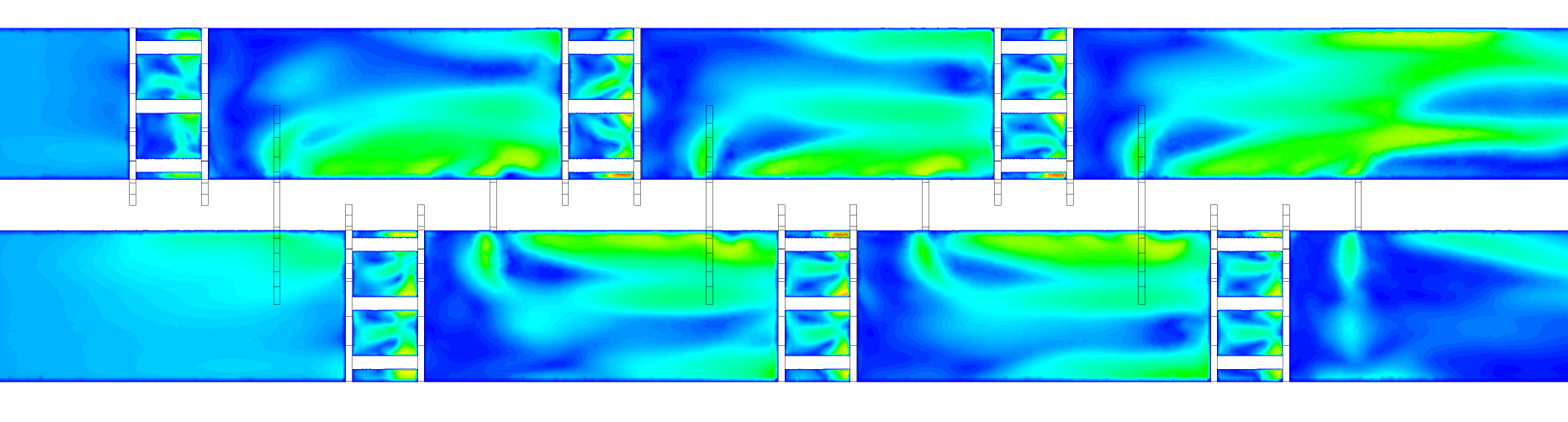

Flow simulation inside Transcal heat exchanger with ANSYS Fluent®

Download brochures

Download the technical sheet